Pickling is a crucial process in the fabrication of stainless steel, especially following welding operations. It refers to the treatment of the stainless steel surface with a mixture of acids (often nitric and hydrofluoric) to remove impurities, stains, rust, and scale that result from welding and fabrication processes. This treatment improves the stainless steel in several ways:

1. Corrosion Resistance Enhancement

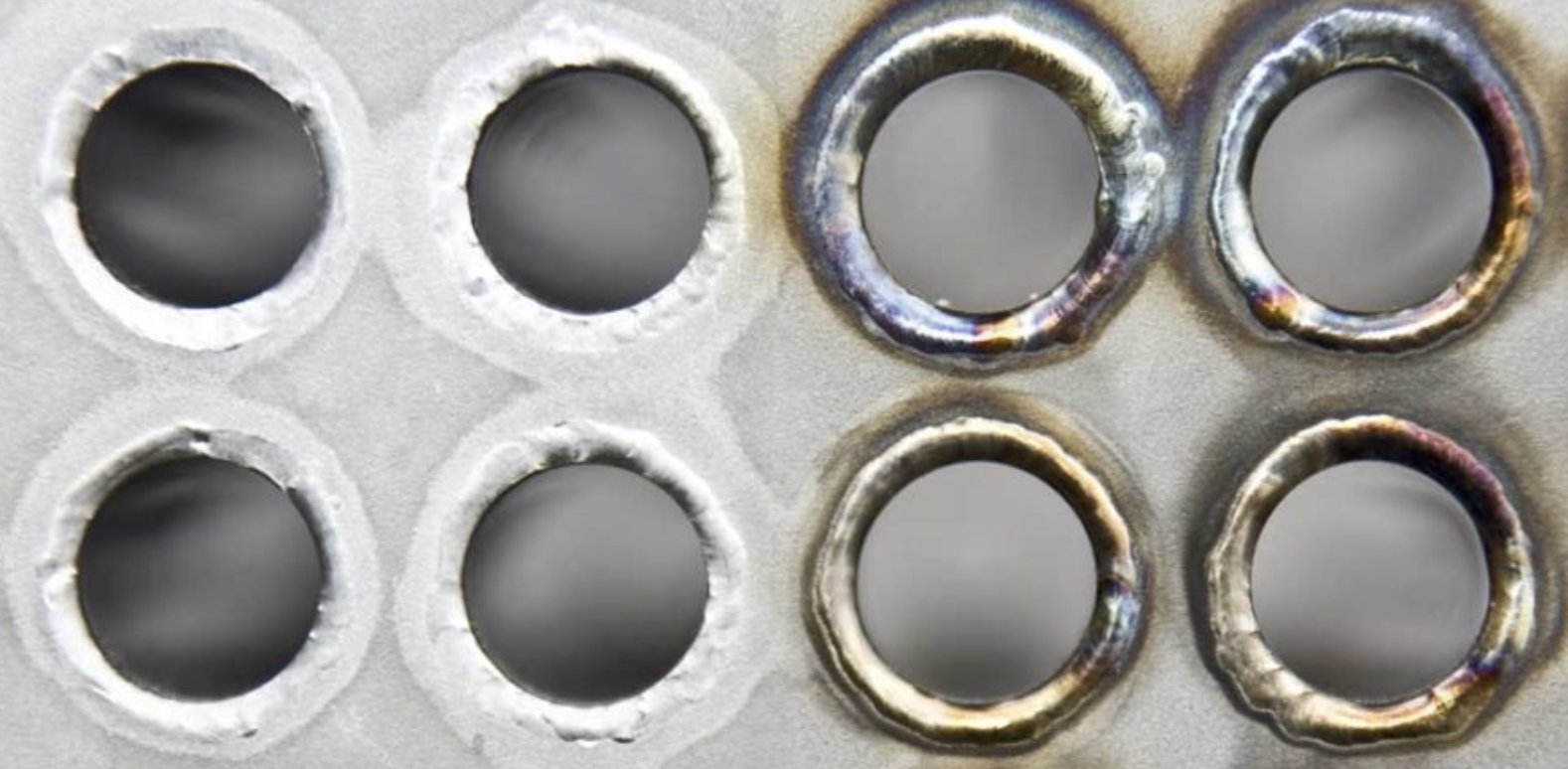

- Removal of Oxidation and Scaling: The primary improvement from pickling stainless steel welds is the removal of the oxidation layer and any scaling that forms during welding. This layer, if left untreated, can interfere with the chromium oxide layer that gives stainless steel its anti-corrosive properties.

- Restoration of Chromium Oxide Layer: Pickling helps in restoring this protective chromium oxide layer. By removing the oxidized surface, the natural passive layer regenerates, thereby enhancing the material’s resistance to corrosion.

2. Aesthetic Improvements

- Uniform Appearance: Welding can leave discoloration and scaling that are visually unappealing. Pickling evens out these inconsistencies, giving the stainless steel a uniform, clean, and attractive finish. This is particularly important for architectural applications of stainless steel where appearance is crucial.

3. Improved Product Life

- Durability: By restoring the corrosion resistance of the stainless steel, pickling extends the life of the product. The removal of corrosive contaminants and weld burns helps prevent premature degradation, thus ensuring durability and structural integrity over time.

4. Enhanced Surface Cleanliness

- Preparation for Further Processing: After pickling, the stainless steel surface is generally cleaner and free of contaminants that could interfere with subsequent processing steps, such as painting or further machining. Clean surfaces ensure better adhesion and quality of coatings and treatments applied later.

5. Increased Safety

- Removal of Harmful Residues: By removing potentially corrosive and abrasive particles, pickling can help reduce the risk of injuries or equipment damage that might occur if these particles were to dislodge during handling or further processing.

6. Consistency in Mechanical Properties

- Maintaining Material Characteristics: By removing the altered surface layer caused by welding, pickling helps in maintaining the consistent mechanical properties of the underlying stainless steel, essential for applications where material performance is critical.

In summary, pickling stainless steel welds not only enhances the aesthetic and physical properties of the steel but also ensures that the material retains its designed corrosion resistance, mechanical strength, and durability. These benefits are crucial for maintaining the quality and longevity of stainless steel components across various industries, from construction and automotive to food processing and medical equipment.